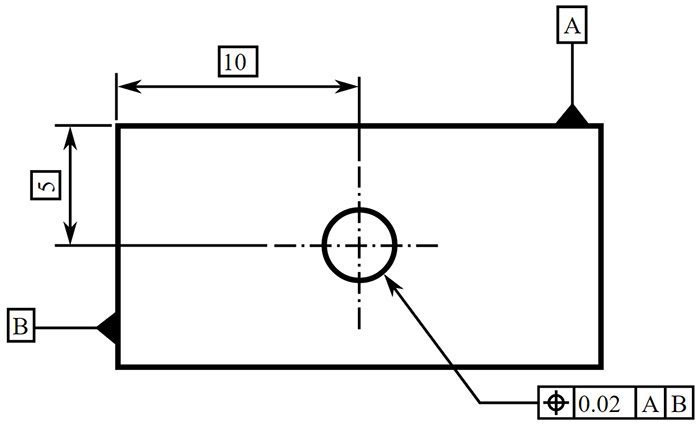

This blog post showed just a simple example of a datum reference frame and the related specification of tolerances for educative purposes. The Datum reference system itself is formed by the intersection of three datum planes A-B-C (in blue). The tolerance zones (profile and position – in red) are defined with respect to datum reference frame (DRF – at the bottom-left corner) through basic dimensions. As design and manufacturing becomes more decentralized, a standardized distribution of tolerance information becomes more important. The same figure as Figure 3, without the part itself. Geometric dimensions and tolerances, including symbols, datums, and tolerance zones. The distance between these two planes is 5 mm.įigure 3. Similarly, the upper surface of the part should be between the two planes defining the profile tolerance zone located by a basic dimension of 100 mm. This zone is defined by a cylinder of 5mm diameter. This means that once the part is immobilized through 3 datum planes, the center axes of the holes should be inside these tolerance zones located by 4 vertical and horizontal basic dimensions, 75-25 and 40-120 mm, respectively. Using this datum reference system as the common origin, the basic dimensions (the dimensions inside rectangular boxes) define the tolerance zones (in red) for position and profile tolerances. In Figure 2, the datum reference frame at the bottom-left corner is defined by the three orthogonal datum planes, A, B and C (in blue). The Datum reference system itself is formed by the intersection of three datum planes A-B-C (in blue) The tolerance zones (profile and position – in red) are defined with respect to the datum reference frame (DRF – at the bottom-left corner) through basic dimensions. The part defines position and profile tolerances with respect to a datum reference frame through basic dimensions.įigure 2.

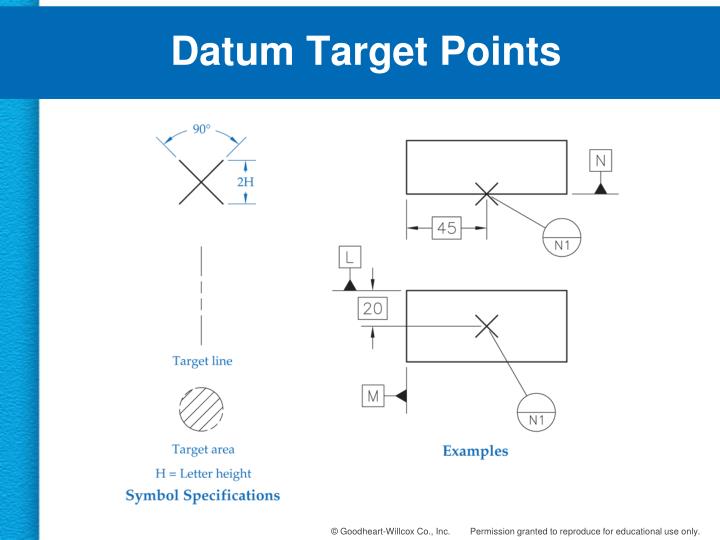

GD&T Symbols Following 14 GD&T symbols are used to control foam, orientation, location, and runout in part geometry. Without this common coordinate system, product definition is unclear, rendering the inspection results unreliable.įigure 1 shows a visual representation of this concept. Tolerance Zone Modifiers: Projected Plane, MMC, LMC. It is the common coordinate system of all tolerance zones. The main function of the datum reference frame is to specify a foundation for the inspection of the part. The tolerance zones are defined with respect to the datum reference frame (DRF – at the bottom-left corner) through basic dimensions.Ī datum reference frame is a coordinate system against which the geometric dimensions and tolerances of a part are defined.

Characteristics Common to US Topo and Traditional USGS Topographic Maps The three-year production cycle of the US Topo program. Please visit The National Map Viewer with the US Topo Availability service enabled to view exact publish dates and access the latest US Topos.

0 kommentar(er)

0 kommentar(er)